Sustainable shipping and the future of maritime electrification – Damen Shipyards leading the way

- Insights

- 16 March 2022

There’s no doubt that electrification is a megatrend that is driving substantial changes in the maritime industry. This change is driven by regulations and politicians, as well as the demand from cargo owners and passengers to become more sustainable.

To meet these challenges, changes are needed in everything from engines and propulsion to integration with utilities and shore facilities. What is not as talked about is the need for adapting business models to suit new demands, and how digitalization and connectivity can be used to optimize operations and design.

The good news is that the ecosystem is booming with innovation, novel solutions and initiatives. In the center of this is the family-owned giant Damen Shipyards. Over 100 years old, but with a brand-new vision to be the most sustainable and connected shipbuilder in the world.

What does this mean? And what is Damen’s view on how the maritime industry will adapt to the challenges of sustainability? To learn more, we sat down with Martin Verstraaten, Sales Manager for the Nordic market, and talked about the future of maritime, the electrification of vessels, and the collaboration between a global giant and an innovator in batteries and fuel-cells.

Martin, by now is a long timer at Damen Shipyards. Starting out in the summer of 2011 as commercial manager at service department for Africa, assisting their direct sales teams in the region.

The assignment meant frequent travelling all around the African continent, to Nigeria, Gambia, and Ghana. In Nigeria, for example, we sold a significant number of vessels annually and needed to increase their local service strength. This meant setting up dedicated services, more or less a complete shipyard with technicians, suppliers, stores, and branding. Actually, i did the same in Ghana and Gambia and worked with this for a few years until 2015. That’s when I changed regions to take on a new position as Sales Manager for Northern Europe”, says Martin.

My initial ambition then was to start working intensely on building relations and network. That meant traveling to countries in the Nordic region meeting both suppliers and customers.

I traveled around in Sweden in late 2016, beginning of 2017, I went from Luleå in the north, further down to Stockholm, all the way to Karlskrona in the south. I met with suppliers and customers and looked for potential companies to cooperate with. One of those meetings was with Echandia. I first read about them in Swedish maritime magazines, and it seemed like an exciting company. At that time, they had built the Movitz (link), and BB Green (link) and were working on taking their concept to the next step. We wanted to know how to participate in similar projects, so we started working with a team from Echandia.

Magnus Eriksson CEO and founder of Echandia

Echandia by the time, had already built up quite a lot of experience with electrification of commuter vessels. I listened to their experience regarding commuter ferries in Sweden and, more specifically, in Stockholm. I got insights into technical operational demands, routes, speeds, vessel configurations, regulations, and the behavior of commuters. I learned a lot and brought the feedback to Damen, Martin explains.

Since those days, a lot has happened in the market for electrical ferries.

Today, our customers aren’t interested in diesel engines. Four, five years ago, the main talk was about diesel, maybe biodiesel, and perhaps it could be interesting to add some hybrid system and implement peak-shaving on larger vessels. But now, our discussions start with batteries. If it’s not possible, due to operational demands, you find a way with hybridization or adding additional charging points along the route.

Q: What about retrofitting? Putting battery systems on old vessels is getting more popular as operators seek to decarbonize – what does an operator need to think about when it comes to retrofitting batteries on a vessel?

Not all vessels are suitable to retrofit to full electrical operations. But, with the right conditions, you can stretch the lifetime of a vessel to 20-30 years when you open the route to investing in retrofitting batteries. The challenge as always, is weight. Some ships are less weight sensitive, but you need to calculate. Does the vessel have sufficient deadweight to install batteries and new switch boards, and can it sail smoothly with the potentially added weight?

Q: Economics matter of course – is there a way to say what’s most economically beneficial – retrofit or newbuild?

Sometimes, the cost for conversion might be higher than the vessel did when you first bought it, though, so going through the financial aspect is essential. Then you need to ask yourself the same questions as with newbuilds. Do you have space for the batteries? Is there enough room for additional systems? What is the required power for your operational profile, and how often do they need to be charged?

Choosing weather retrofitting is the best solution needs to be investigated case-by-case. If it’s not economically viable to retrofit and convert your old vessels to a sustainable solution, maybe it’s better to go for new build. But, when building a new vessel, you need a longer tender period, and more time to build. The investment (CAPEX) on a full-electric vessel is higher, so you want to know that you’re going to get the investment back. On the other hand, as fuel prices (and regulatory demand) drives fuel prices up – the OPEX also becomes lower with electricity. You need to look at both CAPEX and OPEX and compare.

For instance, in the Copenhagen project with Movia, 10+2 years was required to invest in the new vessels. After approximately 7 years you reach positive cash flow for a battery driven vessel and can see the economic benefits of reduced energy costs, and lower maintenance cost that is the case with electric vessels.

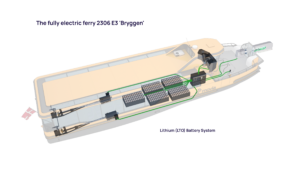

Damen Copenhagen Ferries DFE 2306 Bryggen

An interesting development right now, is that commercial banks will give increasingly more beneficial loans to those that have a green solution included, and investors are willing to invest in green vessels.

In many cases it starts with local politicians setting goals and demanding a particular environmental impact. Without regulatory demands, operators will usually go for the most economical option and if it’s diesel, they will go for that, says Martin on what drives change and maritime electrification.

Copenhagen is a great example. The city had a goal to become the most sustainable city. At the time, the local commuter ferries were diesel-driven, so the mayor of Copenhagen challenged the operators and made it happen by investing in fully electric ferries.

Q: Choosing the right battery system for the right vessel is crucial – how do you evaluate batteries for fully electric vessels?

It all about operational demands. All technology has some limitations, so what’s interesting is what kind of vessel we are talking about and how you plan to use it? We have a model where we collect data from 10-20 different suppliers to better understand how batteries perform. We have collected information about how they charge, discharge, how they perform for the specific operational profile, power demand, and so on. Through this data we better understand which battery suits a specific ship type.

Cutaway image of DFE 2306 Damen Copenhagen Ferries

Most importantly, and what we do in a business case is to look at the demands from the buying entity, and the operator. Depending on the operational profile, we might look for different system characteristics – ones that can handle fast charging, or for longer routes that last longer and can be charged overnight.

We often look for systems that can last for minimum 12 years, with sufficient power also after that period. Otherwise, the option is to change the entire battery system after half that time.

Q: Damen is an impressive company with a great legacy – how do you explain your success today? And where are you in 10 years?

Damen wants to be the most sustainable and connected shipbuilder in the world. Digitalization will play a huge role in the future. To improve our systems and continuously learn, we have made our vessels connected. We can then use that data to improve our systems and learn from operations. There is also important data for the owner who learns to operate more efficiently as you get feedback from energy usage and where you can save. In fact, by learning how batteries function with real, live data, we can stretch the life cycle of the systems.

In the end, there will always be some pollution connected to moving people and goods. Our goal is reducing that pollution as much as possible with good technology while at the same time meeting the boundaries of the operational profile. Diesel and older technologies are out of the discussion today. The solutions must be sustainable.

In the future we will probably become more of a total solutions provider, where we offer new ways of operating and owning a fleet of vessels. Our concept ‘Power-by-the-hour’ means you include everything from the vessel, its operating costs – fuel and power, service, crew supply, logistics. This kind of performance-based contracting offers solutions where the operator pays for the operation instead of being responsible for buying, owning and everything that comes with it, makes life a lot easier for them.

Since the days of living in Africa, to travelling by car along the extended cost line of Sweden, Martin’s life seems a bit more rooted. As most people in the Netherlands, and the rest of Europe these days, we had this talk with Martin from the comfort of his home.

As Sales Manager in the Nordics, Martin regularly visits the countries up north.

I have pending discussions in the Nordic region concerning tugboats, looking at new investments in that segment. Sparky was the first fully-electric tugboat, and there is a steep increase of hybrid and full-electric tugboats in the coming years, says Martin.

RSD-E 2513 Electric Tug Sparky

What’s interesting is that generally, the discussions we have now, has become much broader. Previously, we (just) discussed the actual tugboats for instance. Now we have a much wider discussion, like how large is the port? What is the charging capacity for a fully electric tugboat? What is the availability of energy?

It truly is a time of exploration and innovation. And it seems that the industry, pushed on by Damen is about to meet the goals of decarbonization. We look forward to continuing the development together with Damen Shipyards and Martin Verstraaten.