Marine battery systems explained

- Insights

- 17 December 2021

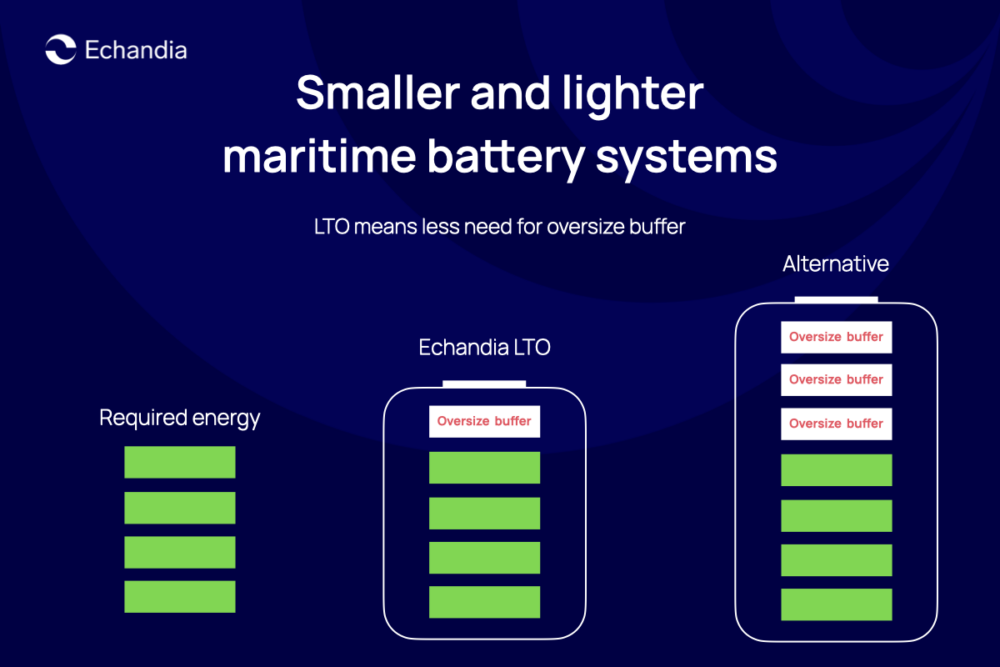

A common misconception with LTO based marine battery systems is that they are heavier and require more space than other solutions. The reason is that we tend to evaluate batteries on a cell level instead of on a system level. Let us show you how the LTO-chemistry in fact can lead to a smaller, lighter system.

The evolution of marine battery systems

After the EV revolution, the maritime world is poised to embrace electrification at scale. For an industry, which has been built on fossil fuels, there is a lot to learn about electric energy storage (ESS).

The growth of EV:s has been powered by Graphite based Li-ion batteries (commonly referred to as NMC), a type of battery with high energy density but with limited cycle life and power output. But not all lithium-ion batteries are created equal, read our comparison of LFP and NMC batteries to get more knowledge.

The problem when evaluating batteries is that we tend to focus on cell characteristics, not system design, capabilities and performance on an application level.

The LTO battery chemistry is often misunderstood as more expensive and heavier, but for maritime applications, its capabilities and qualities often make the system both lighter and more cost-efficient than most other lithium-ion based systems.

Less need for oversizing – smaller and cheaper maritime battery systems

One key concept of dimensioning battery systems for a specific use case is oversizing which, in fact means installing more capacity than required for the intended purpose.

This extra capacity is installed so that the battery can age over time but still perform as was intended when designed.

When planning an ESS for a vessel, a set amount of kWh is often defined beforehand based on prior experience. For the NMC-chemistry (used in a majority of EV:s and vessels), that could be as much as 40 percent excess capacity.

For the LTO-chemistry, the same buffer would only have to be around 20 percent, depending on the usage profile.

With a minimal need for oversizing, the system has a smaller physical footprint (i.e., takes up less space on the vessel), is lighter, and for most operational profiles, less expensive than an NMC system dimensioned to meet the same requirements.

The Echandia LTO system can be dimensioned with lesser margins because of its exceptional cycle life capabilities.

In addition to these apparent advantages of the LTO cell in a system, there are durability and power aspects that we discuss more in detail here.

Get further insights

So, to sum up, when dimensioning battery systems, it is important to reconsider assumptions based on previous experience. Focus instead on the operational profile. Doing so will lead to the optimal configuration based on the various technologies available. This will lead to a system optimized for space, weight, safety and cost.

Would you like to get a better insight into what happens in maritime and the development of marine battery systems? As the maritime world is adapting to electrical energy storage, we see the need to help educate and build knowledge in the ecosystem. Our webinar gives you a crash course in battery dimensioning and a few examples of how LTO batteries and Echandia systems are used in different operational profiles.