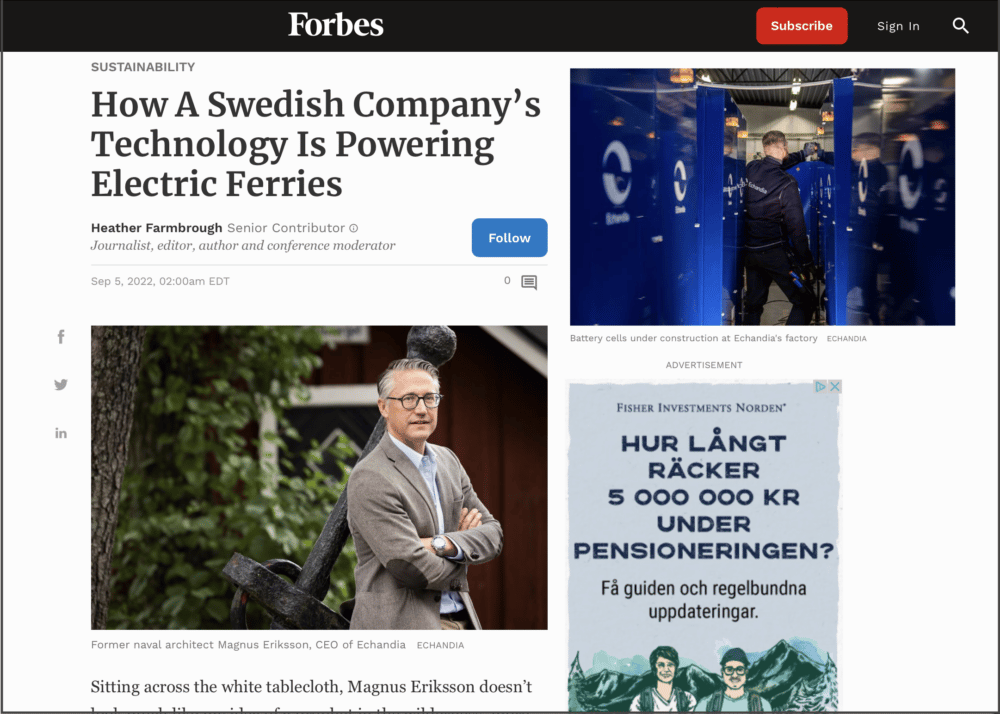

In June, our CEO, Mr Magnus Eriksson met up with Heather Farmbrough – a curious and sustainability minded writer for Forbes. Her interest in sustainability and new technology with its promise for real, change probably gauged her interest in maritime electrification and led her to Echandia.

We feel that the transformation of the global maritime industry from fossil fuel dependency to zero-emission is under reported and not recognized enough. There is a massive change on-going, as policymakers has put pressure on us to change, says Magnus Eriksson in a comment.

Some of the key points made in the article is that shipping has lagged in the electric revolution we’ve seen in automotive. In part because it’s far more complex to make a ship’s battery safe and reliable than for other, lighter applications. The demands are higher, not only for safe operations (at sea), but also for durability and life cycle demands. There’s also an element of ecosystem challenges, with a conservative and traditionally slow moving industry now being forced to change.

However, there is a tipping point and it’s within reaching distance. “Until very recently, it’s been more expensive to operate with electric rather these than diesel,” Eriksson says in the article.

Of course, many of the drivers for the industry is from policy and regulatory impact, such as EU’s Fit for 55 Directive and the IMO (International Maritime Organisation) which is expected to improve its own target of cutting greenhouse gases by 50% across global fleets to 100% by 2050. But localized initiatives are helping to guide the industry in the right direction. In Norway for instance, vessels are no longer permitted to moor up in the city if they are using a diesel engine.

There are huge differences in how far electrified shipping has progress around the world. In Stockholm, waterborne transport is running a long way behind other forms when it comes to emissions-free journeys.

In fact, in many ways India has come further than Sweden because it has focused on becoming emission-free and is moving distinctly towards direct electrification rather than using hybrid solutions, such as biofuels alongside diesel.

The project in Kochi is probably one of the most ambitious maritime electrification projects in the world. It will connect Kochi and its 10 islands over 76 km, linking up with the city’s metro system.

In Copenhagen, Arriva Denmark operates seven green commuter ferries, using Echandia’s lithium-titanate-oxide battery systems. These ferries run 17 hours a day, with each trip taking roughly one hour and can carry 80 people.

Going forward, one of the biggest issues holding back maritime electrification is the need to store huge amounts of energy. Where batteries become too big, or not capable of supplying enough energy before the end of the route, there will other solutions in place, like fuel cells. The great advantage with them is that rather than being bound by charging structure, ship operators carry fuel onboard.

“The key for all large commercial ships is to carry as much fuel on board as possible. Ships take on far more fuel than they need. The problem is storage”, says Magnus in the article.

Diesel has a relatively high energy density which has enabled ships to carry a lot of fuel on board. With alternative fuels becoming more prevalent, but with lower energy density, operators will need to approach charging differently from refueling.

Read the full article on Forbes.com